Our Quick Guide to Laser Cutting

From awesome wall art or beautiful jewellery to branded stencils and creative signage, laser cutting is incredibly versatile. A quick browse online will show you the massive range of laser cut products on offer, the number of possible projects are endless, and the objects you can create are limited only by imagination. So, if you’re asking what is laser cutting, and how does it work? Read on to find out.

What is Laser Cutting?

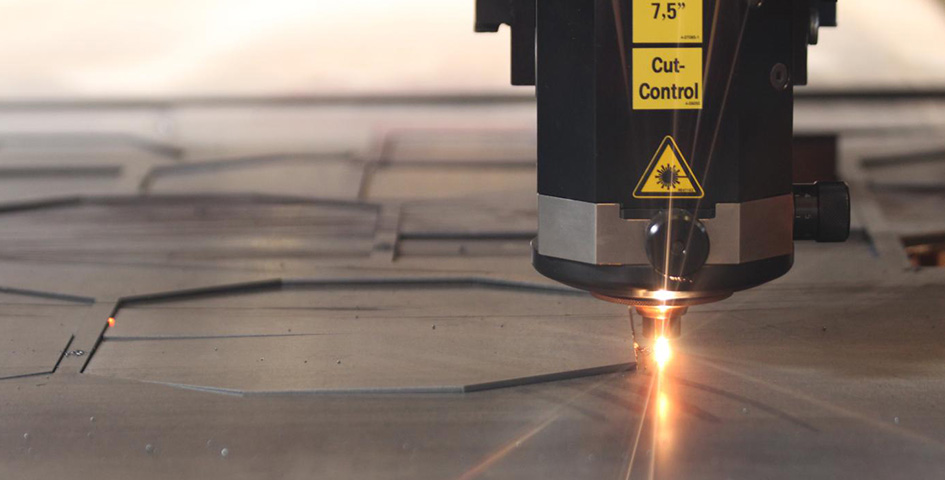

Laser cutting is the process of using a laser beam to trim down a material or cut it into a complex shape that a more conventional tool would struggle to achieve. Laser cutters fire a highly-concentrated laser onto a surface, cutting through it by burning or even vaporising the material. Because of the incredibly focussed nature of the beam, our laser cutters can keep the width of the cut incredibly fine, creating a smooth line and flawless finish.

Laser cutters use CAD drawings to translate a digital design to a real-life product, cutting out the margin of human error and completing cuts to very high tolerance, guaranteeing the finished project quality will be spot on. They can cut a variety of materials including wood, acrylic and sheet metal and the depth of the cut achievable depends on the type of laser cutter being used as well as the type of material being cut. Our laser cutters can cut steel with thicknesses of 0.9-15mm and stainless steel of 0.5-15mm.

The size of laser cut projects can vary enormously, from small one-off items to large intricately cut panels. At Alco, our laser cutters can accommodate individual sheet sizes of up to 3 by 1.5 metres, so very few jobs are too large to complete. With a large stock of sheet metal in-house to choose from we pride ourselves on being able to provide a speedy turnaround, usually just 1-3 days, so you can be sure to see your creation coming to life very soon.

Photo: A selection of our recent bespoke laser cut projects.

If you would like to see your next laser cutting project become a reality, get in contact today by calling 01805 622461 or email [email protected].